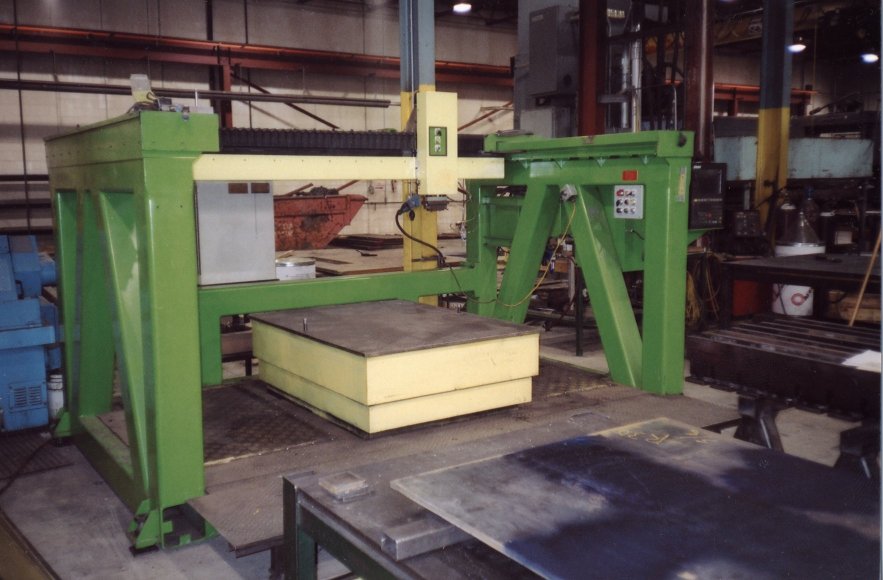

Gantry Style Parts Placement

This project involved the design and manufacture of a precision gantry positioning machine to aid our customers processing of parts. The result was a machine which reduced the customer’s processing time from several hours to twenty minutes. A second machine was made for one of the customer’s other plants. The SCS Group is recognized as a valuable partner in the specialized machine industry.The machine is fabricated from 8" square tubing. It is then heat treated (normalized) to remove stress caused by welding. Next precision machining reference planes are done. Linear ball bearing slides are utilized on the x and y axes. High speed, brushless servo drives are added with motion controls linked to a special CNC control. A precision worktable can elevate approximately 20 inches and maintain level at all times, while supporting up to a 4000 lb work piece.